Usually circuit boards and delicate electronics require soldering with a 5W or less soldering iron because of the heat effects to the circuit board around the area to be soldered.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to fix DJI Mavic Air 2S Critical Error

- Thread starter BSauce955

- Start date

I don't use an electronic solder iron. It's a gas/fire solder iron.Usually circuit boards and delicate electronics require soldering with a 5W or less soldering iron because of the heat effects to the circuit board around the area to be soldered.

D

Deleted member 103366

Guest

Core board is the main board. Other board is the ESC board. If you cannot pair with drone I would start with core board issue.What are core boards? The mainboard?

Ohflyingbrick

Member

Ok, now that the options are starting to run low, can the drone now be sent to Dji even if the owner has tried to do the repairs? I’ve a 3yr old 2 with no insurance nor dji repair offers and am worried enough about crashing/flyaway to the point I hardly ever fly anymore. If I now ask dji for repairs will dji sting me heaps of $ for the even smallest repair or just say no fix available, go away?

Are you saying that even with the critical error, I should still be able to pair with the controller? Also, I've never paired it with this specific controller so I'm talking about real pairing, and not just connecting to a previously paired controller. Maybe I should've used the word "bind"....Core board is the main board. Other board is the ESC board. If you cannot pair with drone I would start with core board issue.

Yes I did, what am I supposed to be looking for?Did you look closely at the cable with a magnifying app or glass?

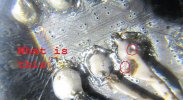

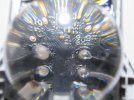

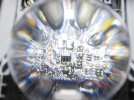

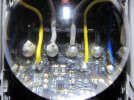

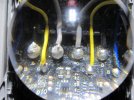

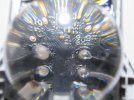

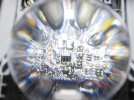

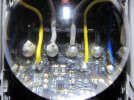

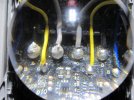

Here's a bunch of detailed pictures. I haven't had the chance to go through them all yet but I have a feeling I know what the verdict will be. But, I won't say anything. Let me know what you see. For some reason, it's looking extremely dusty, but I'm not sure if it's just the camera. When looking at it without magnification, it doesn't look dusty at all.

I also noticed that if you look at the connection on the bottom left of the 6 connections in the picture, that one of the wires from the drone arm appears to be on top of an internal line on the board. Could that be an issue? My soldering is obviously bad. I'm going to buy the top cover and if that doesn't clear the issue, I'm sending it in to DJI.

D

Deleted member 103366

Guest

Whether or not the damage severes/breaks/cuts any track in the ribbon cable.Yes I did, what am I supposed to be looking for?

Deformation of the cable need not necessarily sever tracks but severed tracks would mean a new cable was required.

I do not like the looks of the solder blobs marked 1 & 2 in the first of the attached, especially bearing in mind Dave Maine's comments in post #18.

Nor do I like the downward angle of the joint marked 3, or rather the upward angle of the cable marked 3. Space may be quite limited in that area and a "standing proud" like that cable may foul the underside of the upper case.

However I am more concerned about the area marked "What is this"in the second attached.

If it is cooked flux (which it may be) then perhaps no harm done but I would try to get rid of it by pressing on it with the tip of a finger nail i.e. nothing hard nor sharp and 'shattering' the 'flux' but if it is damage it looks to break at least 2 tracks, red & yellow, and nick a 3rd.

I do not like the well in the solder that I have circled in the RH blob, when I have seen the likes of that before it was due to the solder not taking to the metal (possibly because of a coating) nor do I like the exposed copper in the bulge that I have also circled.

Attachments

roger boivin

Member

J’ai essayé avec les trois piles, mais toujours le même problème. J’ai cependant remarqué un petit bibelot dans un câble sur le boîtier supérieur. Je ne sais pas si c’est assez grave pour créer l’erreur. En voici quelques photos.View attachment 138127View attachment 138128

roger boivin

Member

Cette déchirure dans le câble ruban est substantielle. Toute interruption de la séquence de démarrage lorsqu’elle est activée déclenchera une erreur, qu’elle soit critique ou non. DJI a implémenté cette fonction de sécurité intégrée dans sa conception pour s’assurer que les autres composants sont protégés contre d’autres dommages ou courts-circuits. C’est comme allumer un ordinateur sans disque dur. Il ne peut pas s’initialiser, donc jette une erreur jusqu’à ce qu’elle soit corrigée. Trouver ce câble pourrait être un peu une tâche. Votre soudure semble que le fer était un peu chaud. Beaucoup de chaleur peut provoquer un choc thermique sur d’autres circuits à proximité s’ils sont laissés allumés à une température longue ou supérieure à une certaine température. Cela entraînera également des erreurs critiques.

Many of your joints look "cold". I would suggest getting a solder sucker and redo all connections that look frosty. A good joint should be bright and shiny. Also I have read DJI intentionally uses extra solder on these joints to make them finish much larger than needed. Something to do with making the joint impervious to electro-magnetic interference or something along those lines. In any event I always strive to make finished solder connection like it was from the factory. Large, well flowed and shiny. I would say from looking at your finished joints that would be where I would start. Probably not the board, but faulty connection. aka, "Cold Solder Joint". Good luck. Hope this helps.Are you saying that even with the critical error, I should still be able to pair with the controller? Also, I've never paired it with this specific controller so I'm talking about real pairing, and not just connecting to a previously paired controller. Maybe I should've used the word "bind"....

D

Deleted member 154956

Guest

Ok, from the looks of your photographs you have quite a few, if not most, of all the motor connections presenting as cold solder joints. Which is to say you have way too much solder and when soldered correctly, they should appear as "smooth, shiny with concave fillets" (not blobs of dull solder) where the wires are soldered (flatly) onto their pads. It also appears that you failed to remove the factory applied conformal coating adequately/properly, and instead just burned right through it with your soldering iron. The ribbon cable is definitely damaged and should be replaced as well. (fyi I am a formally trained and licensed micro-miniature repair technician with 40+ years experience.) Personally, if I were in your shoes, I would just pony up the cash to have DJI either fix or replace it, as you will never be able to fully trust your repairs or have knowledge of any hidden damage.

D

Deleted member 154956

Guest

And as a side note, if you are not properly equipped to perform soldering/desoldering on a very small PCB such as these drone's motherboards, its far safer to just clip the motor leads (wires) down a suitable distance away from the solder, and then butt-splice the new motor's wiring onto the cut wire and use some thin sheet heat-shrink tubing to seal the repair. That way you don't have to worry about removing the conformal coating, prepping the solder pad properly and then resealing your repair. The time to repair might be a bit longer but the ease of repair is much better.

Similar threads

- Replies

- 4

- Views

- 700

- Replies

- 78

- Views

- 4K

- Replies

- 15

- Views

- 2K

DJI Drone Deals

New Threads

-

-

Yx DJI Mini 3 Pro Mini 3 Mini 4 Pro Charger Hub with Color LCD Display

- Started by Dogpilot

- Replies: 0

-

2 Pro Ofrinio Beach, Kavala (Tuzla) | Crystal Clear Waters & Summer in in Greek Macedonia

- Started by SkylandGreece

- Replies: 1

-

-