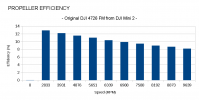

Test conditions: voltage for ESC power supply is 8.8 V, altitude 230 m, air temperature 23 °C

(Note: The efficiency measurement of each propeller affects the efficiency of the motor and ESC used. The measurement of the efficiency of very small propellers from DJI drones is affected by air temperature, air pressure and humidity, which are most noticeable when the motors start to spin up.)

The graph shows that if the propeller reaches 9639 rpm, it has an efficiency of about 8% (8.2% to be exact). However, as the speed increases further, the efficiency drops further, so further increases in speed are no longer relevant to the graph. These speeds produce a thrust of about 64 g and the four propellers thus produce a total thrust of 256 g. And since the weight of the drone is 249 g, at 9639 rpm it starts to climb upwards.

But the propeller efficiency of 8.2% achieved is not dazzling, creating room for significant propeller innovation. The achieved efficiency of each propeller has a major impact on battery life. Instead of increasing battery life, reducing noise or increasing thrust may be chosen, but this requires additional modification of the propeller shape.

The achieved propeller efficiency should be of particular interest to propeller designers and manufacturers. For the average drone owner, efficiency may only be important when he or she starts to wonder how battery life could be extended, drone noise reduced, some record (maximum altitude, etc.) achieved. This can primarily only be achieved by replacing the propellers with propellers with significantly better characteristics.

Maybe some propeller manufacturer (from the EU, USA, Australia, etc.) will take notice of this chart (or all the charts I posted) and show interest in producing the first truly high performance propellers for the most popular drones. I can provide such a manufacturer with more of my aerodynamics knowledge to make the upgraded propellers the absolute aerodynamic cutting edge.

If anyone has one unused original DJI drone propeller at home that I have not yet subjected to efficiency measurements, they can send me the propeller - the propeller may be used, slightly worn, etc. It will contribute to a good cause.

Last edited: