That's true, but unlike the other batteries, there's still voltage. There's also a bit of current due to how the power button and its circuit works.there is no current flow even in the MM or Mini 2 unless you try to remove the battery while it is turned on ,you should never connect any battery into a live circuit as it will spark as it makes contact

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

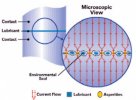

Electrical contacts of the drone with the battery.

- Thread starter mario54

- Start date

Could just be ordinary dirt. My couch has black spots and I don't think that's from static electricity. [emoji16]

1. Lubricants prevent corrosion: true Without the protection of the lubricant, metal contact is extremely susceptible to corrosion. The lubricant "seals" the contact from oxygen, moisture, aggressive gases and other hostile elements. In applications where the connector is exposed to atmospheric agents it is recommended to fill it with grease before connection. The grease acts as a seal against environmental conditions. 2. The lubricant interferes with conductivity: false It is not the grease that attracts the dirt, but the magnetic field. It is true that the external contaminating dust sticks to the grease, but this means that the lubricant is doing its job. Lubricants-electrical-connections The lubricant on the connector creates an external environmental barrier to keep dust, dirt and moisture away from electrical contact. Without this protection, the metal would oxidize much faster. Long tests and experiences have virtually shown that there is no difference between lubricated and non-lubricated contact. The surface of the electrical contact is formed by a series of microscopic ridges and depressions. The passage of the current occurs exclusively through the asperities. The lubricant, present in the depressions, protects the metal from oxidation while the one on the roughness is displaced laterally with consequent passage of the current. 3. The lubricant reduces the insertion effort: true A thin lubricating layer can reduce the effort required to insert the connector by up to 80%. In multi-pin connections or located in hard to reach places, the reduction of insertion effort ensures a correct and effective connection. Some lubricants are also able to make connectors fall within USCAR standards for insertion effort. 4. Gold-plated contacts do not need grease: false Contact manufacturers apply a thin coating of gold over the metal substrate. Coverage is microscopically porous and can be easily compromised, even early on. Over time, oxide formation on the metal substrate can leak through the pores of the non-lubricated contact and cause open circuit resistance. A thin lubricating film, at a much lower cost than a gold layer, closes the pores and protects against scratching during assembly and the development of oxidation on the substrate. 5. Grease Attracts dirt: false Wondering if you need a grease for contacts or electrical connections? Here are some realities and legends to help you make the right decision for your project. If the cost increase is a very important factor, consider that the lubrication of a 6.35 mm terminal, with an appropriate synthetic grease, costs a few cents. 6. The lubricant cancels the effects of micro-movements: true Metals in contact are subject to corrosion caused by microvibrazones (fretting corrosion). The abrasive action derives from low-flow vibrations caused by movement, thermal expansion or contraction. Metal abrasion can build up and interrupt the connection. The lubricant eliminates wear from metal-metal contact and protects the contact from corrosion caused by micro-movements. 7. Lubricants Save Money - True Lubricants improve performance and extend the life of electrical contacts. As a result, the lubricant reduces warranty costs and improves brand quality.

Attachments

careless

Well-Known Member

STS-Mavic-Mini

Well-Known Member

WD-40 is a wonderful product, but I wouldn't recommend it for this application. The WD stands for water displacement. The 40 is derived from the fact that 39 other formulations were tried before achieving the desired properties on the 40th try. It's a water displacement product, and not a great lubricant. But it does a great job of cleaning off the Winter grime from my stainless steel barbeque lid!I do not know if it can be useful, I occasionally clean the contacts of the drone with a small piece of cardboard covered with paper towels, wet with a deoxidizer for electrical contacts, because I think that where a lot of electric current passes, after a while some light forms carbon deposits that could compromise the operation of the drone.I would like to know what you think.

An addendum - if DJI indeed uses gold surface contacts, they should not oxidize. Gold is inert. They should not need any kind of cleaning - certainly not anything abrasive, and not oily.

Patrickgood

Well-Known Member

- Joined

- Mar 23, 2019

- Messages

- 111

- Reactions

- 32

LA 2020

Well-Known Member

80% of electronic device issues can be solved with a shot of spray tuner cleaner (purchased at any electronics supply) or a re-soldered "cold solder". Anywhere there is a mechanical electrical contact it is subject to corrosion leading to a break in the circuit. Cold solders are a result of drops, shaking, etc.I do not know if it can be useful, I occasionally clean the contacts of the drone with a small piece of cardboard covered with paper towels, wet with a deoxidizer for electrical contacts, because I think that where a lot of electric current passes, after a while some light forms carbon deposits that could compromise the operation of the drone.I would like to know what you think.

Unfortunately LA 2020, if the problem stems from a cold weld, all that remains is to disassemble the drone (I would never do it, but I would send it to assistance); unfortunately this only comes from luck or misfortune.

Actually today's electronics suffer more from deteriorated capacitors than other issues. Sometimes you can tell which ones by their bulging but other times you can't tell unless you understand the circuit and symptoms.

rstcso

Member

Not all contact cleaners are created equal. Repaid1 has given the best advice, use DeoxIT Gold. Others have agreed.

I used to own an electronics repair company. You'd think I was a snake-oil salesman with all the praise I've given this stuff. Before the Gold, Caig had some red stuff which worked on potentiometers when nothing else would. They really upped their game with the Gold.

When plasma tvs came out, Panasonic was one of the major players. They recommended using ONLY DeoxIT Gold on the ribbon connectors from the panel driver boards to the plasma panels. Although small (and many), these carried a lot of current. If you used the DeoxIT Gold, you could feel confident things would work when reassembled.

Guitar Center is another source for the DeoxIT Gold. Around $20 for a 5oz can which will last the casual user the rest of their life, except they do have an expiration date on the cans.

I relinquish my spot on the soapbox.

I used to own an electronics repair company. You'd think I was a snake-oil salesman with all the praise I've given this stuff. Before the Gold, Caig had some red stuff which worked on potentiometers when nothing else would. They really upped their game with the Gold.

When plasma tvs came out, Panasonic was one of the major players. They recommended using ONLY DeoxIT Gold on the ribbon connectors from the panel driver boards to the plasma panels. Although small (and many), these carried a lot of current. If you used the DeoxIT Gold, you could feel confident things would work when reassembled.

Guitar Center is another source for the DeoxIT Gold. Around $20 for a 5oz can which will last the casual user the rest of their life, except they do have an expiration date on the cans.

I relinquish my spot on the soapbox.

Similar threads

- Replies

- 32

- Views

- 3K

- Replies

- 8

- Views

- 796

- Replies

- 5

- Views

- 1K

- Replies

- 8

- Views

- 938

- Replies

- 16

- Views

- 1K

DJI Drone Deals

New Threads

-

-

3 Iskar reservoir in fog, ice and many birds

- Started by alex_markov

- Replies: 0

-

-

Mini 5 Pro Flying DJI Mini 5 Pro at −24 °C - real winter test from Canada

- Started by trisen1981

- Replies: 0

-

Members online

Total: 4,605 (members: 11, guests: 4,594)