You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mavic Pro Motor Mod

- Thread starter chazz

- Start date

I have done similar things like this before. Get some thin wire/string and eye-screws and fashion something similar to this:

EDIT: if you do not care about ever folding the front rotor arms, a little epoxy in the joint will permanently secure it.

View attachment 38469 View attachment 38470

That's great! Thank You! I screwed the eye bolts into the printed motor mounts..

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Send pictures pleezThat's great! Thank You! I screwed the eye bolts into the printed motor mounts..

I ordered these hooks to make it quick release..

https://www.amazon.com/gp/product/B016R07H52/ref=od_aui_detailpages00?ie=UTF8&psc=1

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

So close...

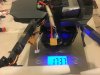

I just completed swapping the main motherboards from my platinum to my dead pro (I do not recommend anyone doing this, it's a royal pain in the a**). Got her all put back together, the go4 app reports zero errors, tried to take off and got this error.

I am not well versed on how to troubleshoot this. Any recommendations?

On an unrelated topic, does anyone know where the aircraft speaker is (that makes the DJI ringtone when you power on)? Since I swapped the main boards, I don't get the ring anymore.

I just completed swapping the main motherboards from my platinum to my dead pro (I do not recommend anyone doing this, it's a royal pain in the a**). Got her all put back together, the go4 app reports zero errors, tried to take off and got this error.

I am not well versed on how to troubleshoot this. Any recommendations?

On an unrelated topic, does anyone know where the aircraft speaker is (that makes the DJI ringtone when you power on)? Since I swapped the main boards, I don't get the ring anymore.

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

The sound is the ESC pulsing the motors themselves.

When you say main motherboard do you mean the ESC board? Were both aircraft on the same firmware, or did you reflash after the install?

I moved both main boards, so in theory it is still the same bird, right?

I moved both main boards, so in theory it is still the same bird, right?

Yes, they should both work as before. The ESC board will give you the boot up tones even without a core board attached as that's just the ESC initialization sound.

Do the motors turn at all on startup? Try reflashing the entire firmware just to be sure.

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Yes, they should both work as before. The ESC board will give you the boot up tones even without a core board attached as that's just the ESC initialization sound.

Do the motors turn at all on startup? Try reflashing the entire firmware just to be sure.

Everything looks normal except the DJI ringtone doesn't happen. All four motors "wiggle" too at power on.

Everything looks normal except the DJI ringtone doesn't happen. All four motors "wiggle" too at power on.

When you CSC start the motors do they spin and idle? Also try starting them with RC only, no device connected. If the motors idle but the AC won't lift off, that could simply be a NFZ issue.

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

No motor spin, I get that error immediately after attempting csc takeoff.When you CSC start the motors do they spin and idle? Also try starting them with RC only, no device connected. If the motors idle but the AC won't lift off, that could simply be a NFZ issue.

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Everything looks normal except the DJI ringtone doesn't happen. All four motors "wiggle" too at power on.

I rechecked the solder points at the motor leads and a couple were sketchy and redoing them now.

For some reason the solder/flux I am using is not sticking to these p3 motor leads very well. But it sticks fine to the wire I am connecting to it??

Anyone experienced this before?

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Lolo, do you have an updated picture of this bird??Interesting reading, and I would bolt on any prop configuration that would outperform my current 2 blade setup.

Platinum with APC 1045 front and 8745 rear.

Lolo, do you have an updated picture of this bird??

This one is officially retired after a lithium fire. Got an in flight motor obstruction error, was still running on 3 motors but not exactly controllable. Shut the motors off and let it drop in an open industrial space but the bottom mounted battery punctured.

What's interesting is that the error was left front, but that prop looks to be in great condition after touchdown. The motor is still bolted securely to the arm so I'm not sure what happened exactly. ESC temp was 90 at the time.

Last edited:

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

This one is officially retired after a lithium fire. Got an in flight motor obstruction error, was still running on 3 motors but not exactly controllable. Shut the motors off and let it drop in an open industrial space but the bottom mounted battery punctured.

What's interesting is that the error was left front, but that prop looks to be in great condition after touchdown. The motor is still bolted securely to the arm so I'm not sure what happened exactly. ESC temp was 90 at the time.

Nobody will ever top this epic crash-n-burn !!!

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Try scraping the wire with the tip of a blade to get rid of any coating or oxides.

That was strange. These motor wire leads have a clear coating that wire strippers don't catch. Had to get a fine file and file off the coating. Never seen wire prepared like this before.

beanbubba

Well-Known Member

- Joined

- May 7, 2017

- Messages

- 1,845

- Reactions

- 1,408

Here are the final rear arms I installed on my mavic today. Had to rotate the motor mount 2 degrees to become level when installed. And beefed up the entry peg walls to allow for an external screw to lock the rotor arm in place by screwing through and into the material. I experimented with several size screws, but you need a beefy one to handle the extra weight and extra long arm on this mod.

Now starting on the front arms, wish me luck

Now starting on the front arms, wish me luck

Attachments

I was just thinking that if the arms aren't going to pivot, the final design could integrate the mounting points to the mid frame and be all 1 piece. That would reduce stress concentrations at the small OD of the cylinder and where any screws go in.Here are the final rear arms I installed on my mavic today. Had to rotate the motor mount 2 degrees to become level when installed. And beefed up the entry peg walls to allow for an external screw to lock the rotor arm in place by screwing through and into the material. I experimented with several size screws, but you need a beefy one to handle the extra weight and extra long arm on this mod.

Now starting on the front arms, wish me luck

View attachment 38670 View attachment 38671 View attachment 38672

Similar threads

- Replies

- 13

- Views

- 3K

- Replies

- 8

- Views

- 1K

- Replies

- 3

- Views

- 2K

DJI Drone Deals

New Threads

-

3 Second attempt to navigate coming clouds

- Started by alex_markov

- Replies: 0

-

-

-

Air 3 3 Features I Love About New DJI Drones

- Started by VegardBerland

- Replies: 1

-

Members online

Total: 2,785 (members: 9, guests: 2,776)